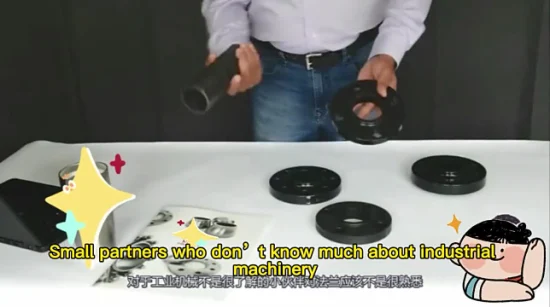

ANSI DIN En BS JIS ISO Forged Steel Socket Weld Flange for Oil Gas Pipeline

Description Flange 1. Application: For seal or connect of pipe/tub-e lines 2. Material: 304,304L,316,316L,carbon steel o

Description

Basic Info

| Manufacturing Way | Forging |

| Application | Oil and Gas Industry, Chemical Industry |

| Certificate | DIN ASME GB JIS Bsw |

| Transport Package | Plywoods/Pallet |

| Specification | PN16 TYPE01 8" |

| Trademark | OEM |

| Origin | China |

| HS Code | 7307910000 |

| Production Capacity | 2400ton/Year |

Product Description

Description| ASME B16.5 .B16.47. B16.36.BS.MSS.AWWA | ||

| Type | Weld Neck flange , Lap Joint Flange , Threaded flange, Socket Welding Flange, Blind Flange, Slip on Flange . | |

| Material | Stainless steel , Alloy steel.. Duplex/Super Duplex, Aluminum | |

| Size | 3/4"-60" | |

| Pressure | 150#,300#,600#.900#,1500#,2500# | |

| Technics | Forged, | |

| Connection | welding | |

| Sealing surface | FF RF M F M TG RJ | |

| Surface treatment | Anti-rust Oil, | |

| Producing process | Billet-cutting-forging-heating-lathe-drilling-inspection-marking-packing-export-din flange | |

| Application Fields | Chemical Industry /Petroleum Industry /Power Industry/Metallurgical Industry Building Industry /Ship-building Industry | |

| Supply Capacity | 8000tons per year | |

| Min Order Quantity | 1 ton | |

| Inspection | factory in-house self check or Third Party inspection | |

| PACKING | plywood cases, pallets, nylon bags or according to the customers' requirements,plastic cap | |

| Delivery | It is generally Within 25 days after receiving your payment | |

| TRADE TERM | FOB, CNF&CFR, CIF | |

| PAYMENT | TT or L/C | |

| CERTIFICATES | ISO-9001/2000,PED,ABS.TUV.DNV | |

Flange

1. Application:

For seal or connect of pipe/tub-e lines

2. Material:

304,304L,316,316L,carbon steel or other material on request

3. Standard:

ANSI,DIN,JIS,BS,EN1092-1

4. Size:

DN15 (1/2") to DN5000 (200")

5. Type:

Threaded Flanges, Socket Welding Flanges, Blind Flanges, Other Flanges

Types' Specification

Welding neck

1, Preferred for high-pressure, subzero or elevated temperature

2, Hub is tapered and bored to match pipe's inside diameter so flow is not restricted, preventing turbulence and reducing erosion

3, Easily radiographed and provides excellent stress distribution

Slip-on

1, Not normally used in high-stress applications due to low hub and weld attachment

2, Silps over outside of pipe

3, Inside of flange welded at hub and end of pipe

Lap joint

1, Used where bolt alignment or access for cleaning is required

2, Similar to slip-on flange when used with lap joint stub end

3, Radius at intersection of flange face and bore to match lap joint stub end

Threaded

1, Used where welding would would be hazardous

2, Designed for low-pressure and non-cyclic applications

3, Bore is threaded to match pipe thread

4, Tapered to seal pipe and flanges

Socket welding

1, For small-diameter chemical processes, hydraulic and stream distribution lines

2, Similar to slip-on flange

3, Counter bore matches pipe bore, allowing unrestricted flow

4, Counter bore from hub side fits pipe's outer diameter - can insert pipe in socket with fillet weld at hub

Blind

1, Used to close ends of piping

2, Has no bore

3, Permits access to sealed lines

Other flanges

Orifice, Expander, Reducing, Lightweight, Studding Outlets, Long Weld Necks,Metric, Navy Drawings, Customer Drawings

Any Requests you can contact us for catalogues. Thanks.

Prev: Pipe Fitting Hot Dipped Galvanized BS Thread Light Pattern Without Bolt Hole Round Flange

Next: ANSI, DIN, En1092, JIS, BS Standard Forged Steel Flange

Our Contact

Send now