Stainless Steel Double Ferrules Tube Fittings Compression Tube Fitting Male Connector

Stainless Steel Double Ferrules Tube Fittings Compression Tube Fitting Male Connector Features: Twin ferrule fittings pr

Description

Basic Info

| Model NO. | MC |

| Body Materials | 316s.S.,316ls.S.,304s.S.,304ls.S. |

| Tube O.D | 1/16 to 11/2 in , 2 mm to 38mm |

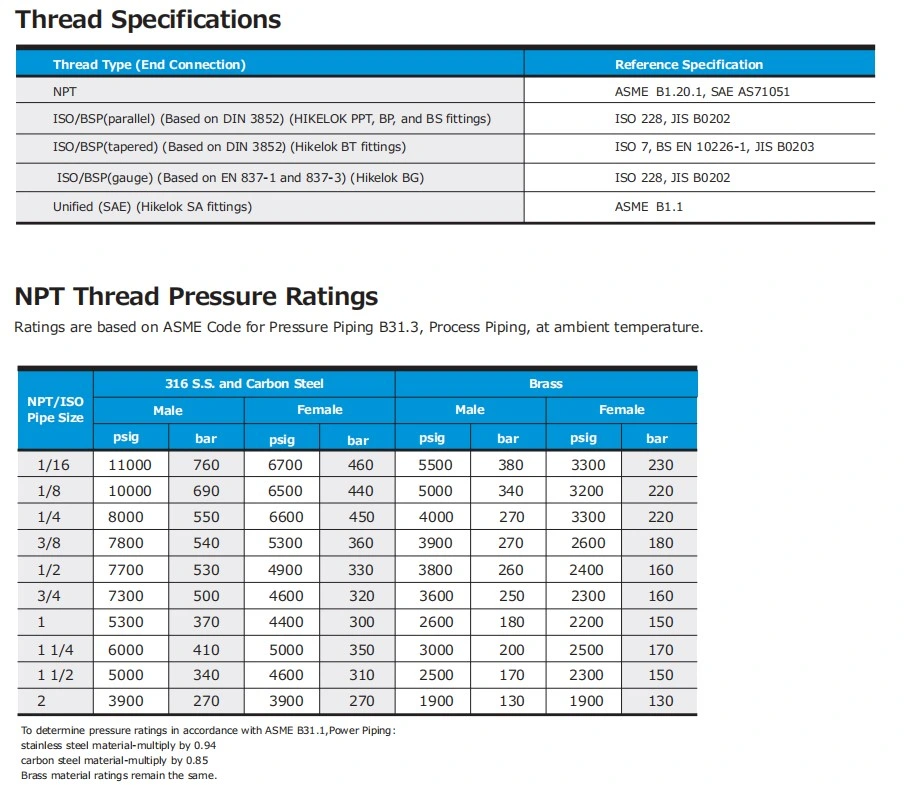

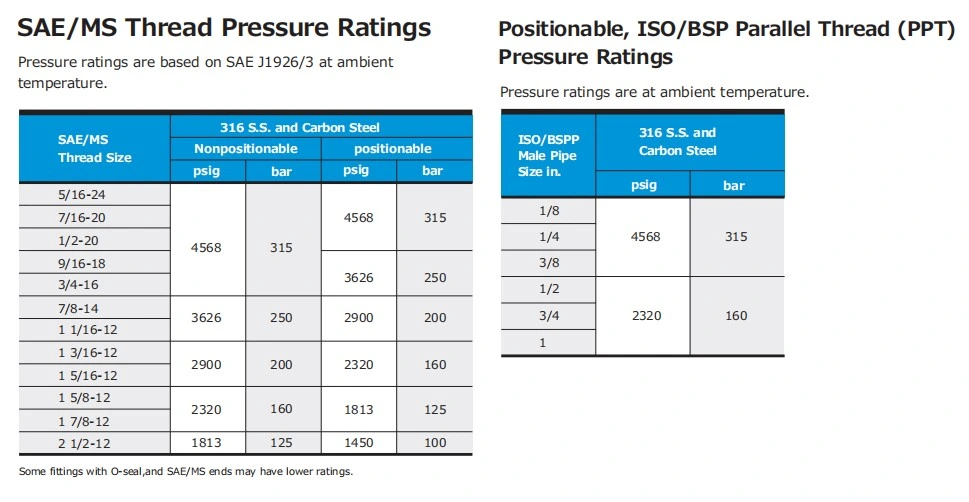

| Thread | NPT;BSPP; BSPT; ISO |

| Cleaning Process | Standard Cleaning and Packaging (Cp-01) |

| Certificate | ISO9001;ISO14001&45001;ABS;CE |

| Transport Package | Carton; Wooden Case |

| Trademark | Hikelok |

| Origin | China |

| HS Code | 7307290000 |

| Production Capacity | 5000 PCS Per Month |

Product Description

Stainless Steel Double Ferrules Tube Fittings Compression Tube Fitting Male Connector

Features:

Twin ferrule fittings provide metal-to-metal seal connections, non-elastomeric seals for leak-free connections

Hikelok twin ferrule fittings are designed to have a maximum allowable working pressure that is higher than that of any tubing

Industry standard design for all instrumentation grade tubing

Stainless steel tube harderness: the hardness of the tube shall be not greater than 85 HRB

Available in sizes from 1/16 to 2in and 2 mm to 50 mm

Hikelok fittings materials include 316 stainless steel, steel, brass, aluminum, nickel-copper, Hastelloy C, 6Mo, Incoloy 625 and 825

Hikelok special treated back ferrule is to provide secure

Silver coated threads to reduce galling

Leak-proof joints capable of satisfying high pressure vacuum and vibration applications

Performance:

Hydraulic proof pressure test (1.5 times the maximum permissible working pressure): no leakage

Dismantling and reassembly test (dismantle 10 times): no leakage

Minimum hydrostatic pressure test (4 times the maximum permissible ambient pressure rating): no leakage

Vacuum test (1 × 10−4 mbar or greater): the leak rate less than 1 × 10−8

Maximum static gas pressure test (with nitrogen gas to 150% of pressure rating): no visible bubbles

Hydraulic impulse and vibration test (the pressure impulses at between 0.5 Hz and 1.7 Hz and the vibration at between 23 Hz and 47 Hz): no leakage

Thermal cycle test (ambient to +80 °C and then to -25 °C with a hydrostatic pressure): no evidence of leakage

Pneumatic pressure vibration test (The frequency of vibration shall be set at 45 Hz and complete 20 × 106 cycles): without failure

Fire test (in accordance with BS ISO 19921): no leakage

Corrosion resistance test (the duration of exposure at least 168 h): no visible evidence of corrosion

Deep water submersion test (equivalent to 3048 m of sea water): no helium detected

Company Introduce:

Introduction of Hikelok® Brand1.Established time: in 20112.Experience/Advantage:focused on precision fluid fittings and valves for more than 10 years.We enjoy a good reputation in the foreign business .3.Product's style is similar to well-known brand Swagelok ®and Parker ®.4.Products introduction:the main products of hikelok include ball valves,needle valves,instrument manifolds,bellows valves,check valves,twin ferrules series tube fittings,instrument pipe fittings,weld fittings and other kinds of instrumentation valves and fittings.5.Body materials: stainless steel,alloy steel, brass,special alloy and carbon steel6.Standard products:ANSI,ASME,ASTM,API,MSS,ISO,EN,GB,JB,HG ect.7.Application:widely used in power generation,petroleum,petrochemical,natural gas, semiconductor,laboratory,shipbuilding, steel,chemical industry and other fields8.Certificate:ISO9001 ,2015;ISO14001;ISO45001;ABS;CE

Certifications:

ISO9001 ,2015;ISO14001;ISO45001;ABS;CE

Our Services:

From quote to delivery, we can provide the detailed support you need:1. CAD drawing2. P&ID3. Component selection4. Bill of material5. Professional services such as bending and welding6. Testing to guarantee the system7. Professional packaging and delivery8. Give you solution within 24 hours

Prev: Factory Hot Sale Hose Tube Elbow Connector 90 Degree Hose Plastic Quick Pneumatic Fitting

Next: Ifan Hot Sell Pn12.5-Pn25 Tube Connectors Customized Plastic PPR Pipes and Fittings

Our Contact

Send now